- Focus on

-

To our stakeholders

- To our stakeholders

- Strategy and management

- Environment

- Social

- Governance

- Data and other information

The Schaeffler Group’s corporate culture has always been characterized by long-term thinking and responsible action, which also extends to the topic of sustainability as one of the four corporate values. A lot has happened since the Schaeffler Group published its first Sustainability Report in 2016. For example, the company established its sustainability roadmap in 2019 and has continued to develop the sustainability strategy ever since. Specific climate targets were also defined for the Schaeffler Group for the first time and now complement a variety of sustainability-related targets. The ESG concept, which forms the basis for the company’s sustainability strategy, was further developed in 2023. Schaeffler assumes environmental and social responsibility along the entire value chain. To continue fulfilling this objective in the future, the sustainability strategy is aligned with the dimensions of environment, social, and governance. Ten action fields were established for the three ESG dimensions and were further defined in the 2023 reporting year.

In 2023, the Schaeffler Group began systematically implementing the Climate Action Plan, which was introduced in 2022 to achieve climate targets, throughout the company. The plan consists of concrete targets and measures to promote an emissions reduction path that is consistent with the 1.5-degree target of the Paris Agreement and achieves Climate Neutrality in the Schaeffler Group by 2040. The Schaeffler Group achieved important milestones in climate-neutral production (Scope 1 and Scope 2) in 2023 and reduced greenhouse gases emissions by 23.9 % compared to the previous year. The company was, however, not able to reduce supply chain emissions (Scope 3 upstream) in 2023, and instead reported an increase of 1.6 % compared to the previous year. The Scope 3 upstream categories taken into account are 3.1 Purchased goods and services, 3.3 Fuel- and energy-related activities, 3.4 Upstream transportation and distribution, and 3.5 Waste generated in operations. That makes consistent implementation of the Climate Action Plan in the coming years all the more important. The Schaeffler Group achieved several milestones in 2023. For example, the company expanded its collaboration with H2 Green Steel and will purchase CO2e-reduced steel, which is produced using hydrogen, from the Swedish start-up as of 2026. Schaeffler is working closely with other steel suppliers as well to develop a decarbonization strategy. In the 2023 reporting year, the company was able to switch the first batches of the steel it requires to the CO2e-reduced scrap and electric arc furnace production route.

Ensuring successful implementation of the ambitious, holistic sustainability strategy will require innovation, new ideas, and new technologies that benefit the individual action fields and help achieve the defined targets. After all, sustainability is a core element in the development of Schaeffler products and is deeply interconnected with the topic of innovation. An important step was also taken in this area in 2023 with the introduction of the Sustainable Project Indicator (SPI), which is a key driver of innovation for sustainable products, sustainable purchasing, and sustainable production at the company. With the SPI, Schaeffler can take sustainability into consideration early in the development process for new, innovative products, taking into account all of the key influential factors on the Product Carbon Footprint.

January

The Schaeffler Group’s climate targets have been successfully validated by the Science Based Targets initiative (SBTi). The climate targets therefore align with the targets of the Paris Agreement and, according to the SBTi, are scientifically sound. As a result, they offer a clearly defined path for reducing greenhouse gas emissions.

February

The company concludes an agreement to purchase wind power from Statkraft Markets GmbH. The supply contract takes effect in 2024 and covers around 8 % of of the company’s electricity consumption in Germany.

March

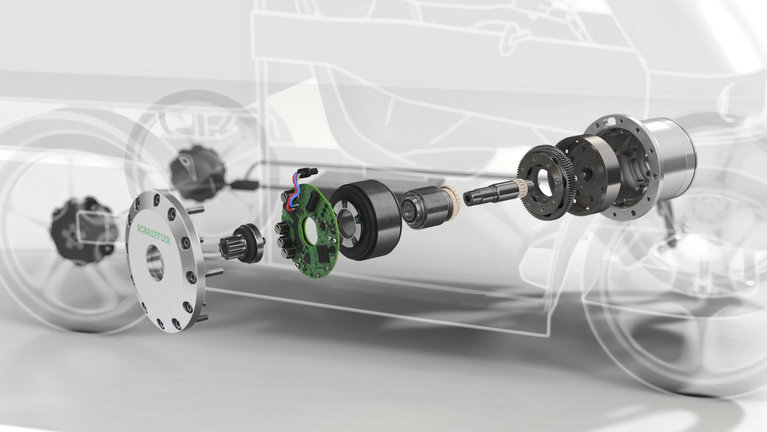

The Schaeffler Group supplies its first customers with the all-electric wheel hub motor. The in-wheel electric motor makes road-sweeping vehicles, compact vans, and snowplows quieter and more agile and enables efficient use of renewable energy. The new drive technology accelerates electrification of municipal utility vehicles and enables new vehicle architectures.

June

The Schaeffler Wind Power Standard ensures maximum reliability in wind turbines. As a market leader and strategic development partner, the motion technology company has supplied reliable bearing solutions for onshore and offshore wind turbines for around 40 years and therefore actively supports generation of renewable energy. The one millionth bearing manufactured in accordance with the Wind Power Standard was delivered in 2023.

June

The Schaeffler Group is expanding its global activities for the development of modern mobility solutions. The company has opened a new state-of-the-art development center in Kysuce, Slovakia, where it develops products and components for e-mobility and vehicle applications such as those used in automated driving.

July

Schaeffler Automotive Aftermarket has commissioned a new photovoltaic system with around 6,000 solar modules at its European Aftermarket Kitting Operations (AKO) facility in Halle (Saale). This system produces up to 2.1 million kWh of electricity annually, therefore ensuring a peak capacity of 2,215 kilowatts.

August

The Schaeffler Group develops next-generation bipolar plates for fuel cell drives Fuel cell stacks with new metallic bipolar plates by Schaeffler exceed the power density of stacks made with previous-generation plates by about 20 %, allowing Schaeffler to demonstrate its development expertise for the future of hydrogen mobility.

August

The Schaeffler Group and VDL plan to jointly develop and produce a new generation of electric and self-driving shuttles for public transportation. These shuttles allow people to remain mobile despite increasing traffic and a lack of drivers while also reducing CO2 emissions and noise.

September

Schaeffler saw its innovative “Free Drive” pedal generator for electric cargo bikes go into fleet-scale production. This core component of a chainless drive system enables all-new bicycle designs and reduces maintenance and wear.

September

The use of green steel produced by H2 Green Steel reduces CO₂e emissions by up to 95 % compared with conventional steel. Green steel is therefore a key lever for supply chain decarbonization.

October

The Schaeffler Enertect coating solution won the renowned MATERIALICA Design + Technology Award 2023 in the “Material” category. The Enertect system makes the production of metallic bipolar plates for hydrogen applications more affordable and even more sustainable.

November

The Schaeffler sustainability platform was nominated for the AutomotiveIT Team Award – Central components include the material supplier database developed in-house, calculation of product carbon footprints (PCFs), and the sustainability manager for decarbonizing the Schaeffler product portfolio.

Sustainable management is one of the major challenges of our time and an integral component of the Schaeffler Group’s corporate strategy. As part of the Roadmap 2025, the Schaeffler Group’s “Sustainability & Engagement” subprogram ensures consistent implementation of the company’s sustainability strategy and achievement of the sustainability targets. The company relaunched the holistic subprogram in 2023, with the Climate Action Plan, which was developed in 2022, integrated as a key element.

A strong network designed to help promote implementation of the sustainability strategy establishes the subprogram in all areas of the company , as successful implementation of the sustainability strategy requires cross-divisional and interdisciplinary collaboration. Sustainability has long been a relevant topic for the entire Schaeffler Group, no longer a niche matter. In fact, it now encompasses all divisions, functions, and regions and has an impact on each and every Group location.

Schaeffler’s sustainability network has established itself since its launch in the 2023 reporting year and creates transparency, which plays a decisive role in the transformation in a global organization with around 83,400 employees. All of the contacts involved throughout the divisions, functions, and regions are closely involved, also on-site at the Group’s locations. All of the members of the network exchange information and coordinate activities in regular workshops and conferences. The roles and areas of responsibility are clearly defined, which allows Schaeffler to respond quickly and flexibly and adapt to new requirements and developments.