Shaping change

Global challenges such as climate change are determining how the mobility and energy sectors are being transformed. Schaeffler, together with its partners, is creating new products and solutions to meet these challenges, ranging from climate-friendly power generation to alternative drives and intelligent repair solutions to new mobility concepts. In doing so, Schaeffler keeps an eye on all future-oriented technologies.

Alternative drives

As a partner to the automotive industry, the Automotive OEM division is meeting the challenge of significantly reducing CO2 emissions in the mobility sector. Schaeffler sees ...

Intelligent repair solutions

The transformation is accelerated by the CO2 limits set by the European Union for new passenger-car registrations that are mandatory for the first time in 2020. The classic ...

Driving the energy transition

A holistic transformation of mobility also requires a transformation of the energy supply. After all, not only industrial machinery, but also increasingly electric vehicles ...

Shaping change

Alternative drives

As a partner to the automotive industry, the Automotive OEM division is meeting the challenge of significantly reducing CO2 emissions in the mobility sector. Schaeffler sees the current change as an opportunity to use its technologies to make the powertrain and chassis more climate-friendly – and to transform mobility together with its customers. At the same time, the company remains open to new technologies and focuses, among other things, on electrifying the powertrain and technologies for fuel cells.

Thinking ahead on e-mobility

Future consumption and emission targets can be achieved by electrifying the powertrain. With its understanding of systems, Schaeffler offers the right solutions for every degree of electrification – for example, both for hybrid powertrains and for purely electric axle drives in the power classes from 15 to over 300 kW.

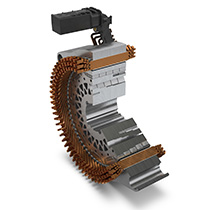

Wide range of applications: electric motors from Schaeffler for hybrid modules, hybrid transmissions, and purely electric axle drives.

E-motors for hybrid modules

Hybrid modules are installed between the engine and transmission, and help to reduce CO2 emissions by 15 to more than 70 percent depending on the design and cycle.

E-motors for hybrid transmissions

The dedicated hybrid transmission combines the advantages of automatic manual transmissions with those of electrified powertrains. At the same time, driving dynamics and comfort are increased while emissions are reduced.

E-motors for electric axle drives

The electric axles can be optimally matched to meet customer-specific requirements due to the modular design of the drive element.

Progressive urbanization is also influencing the mobility of tomorrow. Electric, agile, autonomous, and networked – Schaeffler is shaping this megatrend with innovative mobility concepts like the Schaeffler Mover. Various superstructures can be flexibly mounted on the Schaeffler Mover vehicle platform, from robo-taxis to autonomous delivery vehicles. The Mover development platform, awarded the German Mobility Prize by the German Federal Ministry of Transport and Digital Infrastructure in 2019, uses numerous new Schaeffler technologies such as the Space Drive drive-by-wire technology, the key technology for autonomous and networked driving that is being further developed for large-scale production. Another highlight is the Schaeffler Intelligent Corner Modules. In the four wheel modules, all drive and chassis components including the electric wheel hub motor are combined in one space-saving unit.

Beginning in 2021, we will start series production of electric motors worldwide

Schaeffler Mover: award-winning platform for electric and autonomous driving for urban mobility.

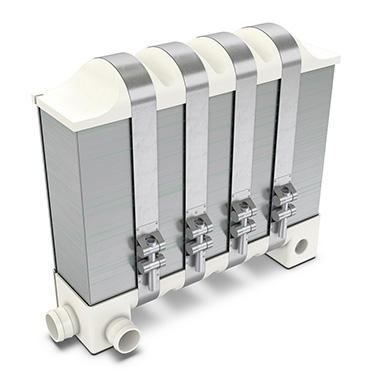

Stacked bipolar plates are an important component of the fuel cell system.

Using the potential of fuel cells

With the goal of maximum sustainability and CO2 neutrality, Schaeffler, as an automotive and industrial supplier, is designing mobility and the associated energy chain. The company is investing in the enormous future potential of green hydrogen along the entire value chain. In addition to all-electric vehicles, fuel cell technologies can also contribute to reducing emissions in the transport sector. The inconsistent availability of renewable energy emphasizes the need for new energy sources and Schaeffler has recognized the great potential of hydrogen as one energy source of the future and developed key components for fuel cells and fuel cell stacks called metallic bipolar plates. To help advance the development of this hydrogen technology, Schaeffler founded the “Bavarian Hydrogen Alliance” with the Free State of Bavaria and other alliance partners in 2019. The goal is to combine climate protection, energy, mobility, and technological innovation and to utilize the potential of hydrogen technology as an energy source of the future.

Shaping change

Intelligent repair solutions

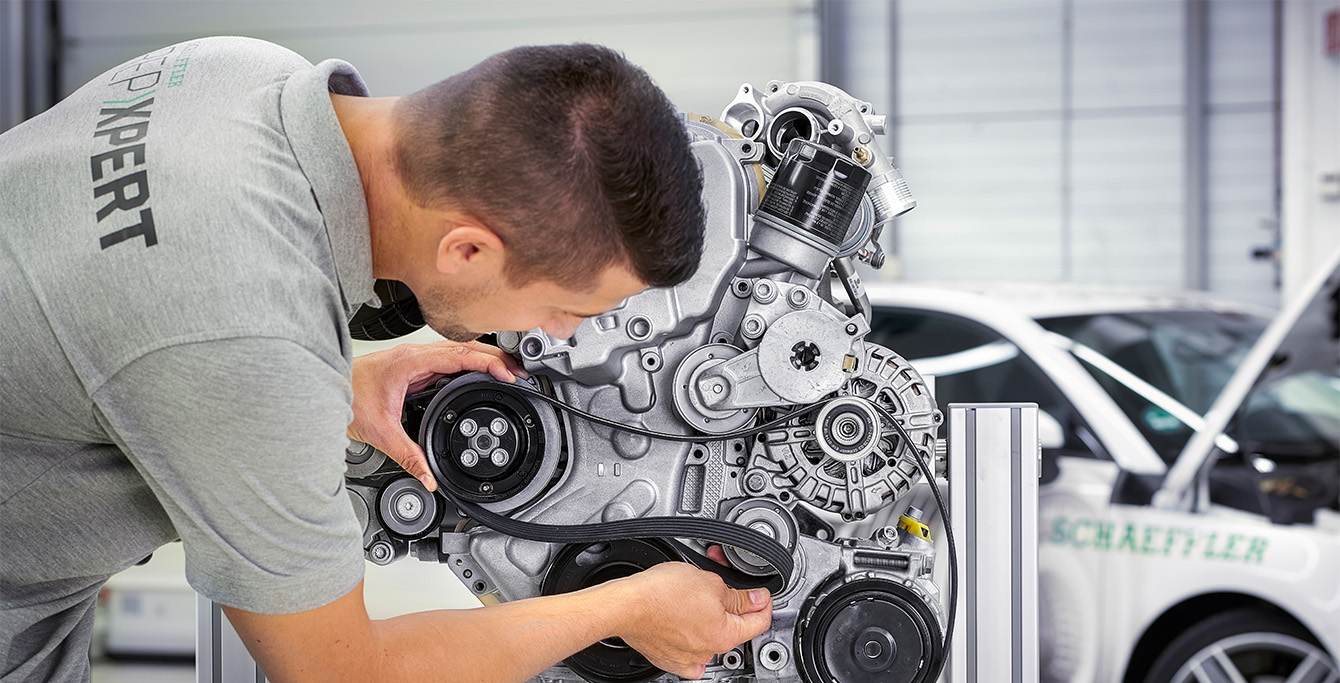

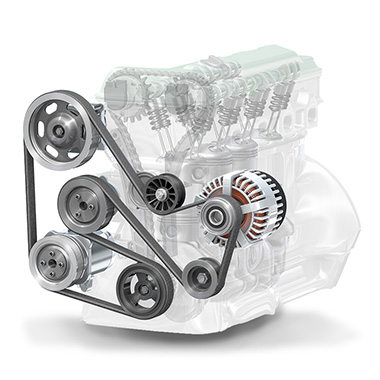

The transformation is accelerated by the CO2 limits set by the European Union for new passenger-car registrations that are mandatory for the first time in 2020. The classic combination of combustion engine and transmission is increasingly being supplemented by hybrid and electric components. The advanced technical complexity of these vehicles also requires innovative repair solutions and spare parts with which the Automotive Aftermarket division offers resource-saving solutions for the spare parts market.

Climate-friendly repairs

Technologically, Schaeffler is excellently positioned for hybrid vehicle generations with its original equipment expertise. The 48-volt mild-hybrid technology is key to developing repair solutions: For the first time in automotive history, this technology transforms the engine’s auxiliary drive from an energy consumer to an energy supplier. With the INA FEAD KIT, Schaeffler is the first supplier in the spare parts market to offer a repair solution for the front end auxiliary drive (FEAD) in hybrid vehicles with 48 volts, which enables stricter CO2 regulations to be met.

potentially saved CO2 emissions

Here the starter and alternator are replaced by a belt alternator starter. In combination with a 48-volt battery, the vehicle can “coast” with the combustion engine completely switched off, which saves up to 7% of CO2 emissions in road traffic.

Energy-saving repair solutions for hybrid vehicles are a central component for a holistic transformation of mobility

The INA FEAD KIT enables efficient repair by replacing all affected components in a single work step.

Shaping change

Driving the energy transition

A holistic transformation of mobility also requires a transformation of the energy supply. After all, not only industrial machinery, but also increasingly electric vehicles all over the world need to be supplied with electricity – and this should ideally come from renewable sources. At the same time, it is important to use our resources sparingly and make energy consumption as efficient as possible. The Industrial division supplies the necessary components for this.

Durable wind turbines

Against the backdrop of major climate challenges, the global demand for renewable energies is growing. As a partner of the energy industry, Schaeffler supports the expansion of renewable energy production. From bearing solutions for wind turbines to solutions for the solar and hydropower sectors, Schaeffler offers its customers a comprehensive product portfolio to make the production of renewable energy more economical. An example is the asymmetrical spherical roller bearings for wind turbines. The bearing of the rotor shaft is of central importance because all of the forces generated by the wind have a direct effect on that bearing. The design of the new spherical roller bearings, which has been specially optimized for rotor bearing arrangements, increases the nominal service life by about 70% compared to conventional spherical roller bearings. This way, Schaeffler helps to make wind turbines more reliable and to reduce the cost of renewable energy production.

70%

increase of nominal service life of spherical roller bearings

As a partner of the energy industry, we promote the expansion of renewable energies

The portfolio now also includes predictive monitoring for variable speed drives in wind turbines. Together with a partner, Schaeffler has developed a compact Industry 4.0 solution. It combines different measuring systems with a new condition-and-torque monitoring system. The system not only identifies and limits peak loads and their frequency, but it also allows early detection of incipient damage. Repairs can therefore be planned in advance for windless days.

Spherical roller bearings are designed for systems in which high loads must be supported. They deliver extremely high performance and are designed to carry extreme loads.

Rolling bearing systems are used in airplanes and spacecraft construction resulting in increased performance, safety and reliability.

tons of fuel can be saved annually

Efficient engines

Rolling bearings in aviation must operate with maximum reliability even under the most critical operating conditions, while at the same time keeping fuel consumption as low as possible. Schaeffler Aerospace fulfills these requirements with its new engine bearings. Together with a cooperation partner, the company has developed ball bearings that exceed the speed parameter of four million millimeters per minute for the first time. Because the bearings require only small quantities of cooling oil, there is a considerable increase in mechanical and thermal efficiency. The bearings represent a significant technological leap forward in the development of more efficient engines and have the potential to reduce the consumption of the global passenger aircraft fleet by up to