Navigating the digital future together

For Schaeffler, the digital transformation is an engine for new processes, innovations, and business models. Sustainable product solutions are at the heart of the transformation – which involves both technological and cultural changes – and are made even more efficient and durable with the aid of digital tools.

Managing digitalization

For Schaeffler, digitalization is a central, cross-sectoral topic that will advance the company along its entire value chain. Various departments shape the digital transformation accordingly within the Schaeffler Group. To underline the significance of the topic, the departments involved were united in early 2020 to create a new, strategic Digitalization department at the Nuremberg location – with a direct reporting line to the Chief Executive Officer. The restructuring also bundles the topic spatially: The team members of the central IT and Digitalization departments work together at the Air Campus in Nuremberg, which with its modern New Work concept offers a work environment that promotes innovation and transformation. Protecting information and data is extremely important to Schaeffler, which is why maximum cybersecurity is always ensured for all internal and external digital solutions.

More information on data protection, information security, and cybersecurity

The new Air Campus Nuremberg bundles different areas of digital expertise.

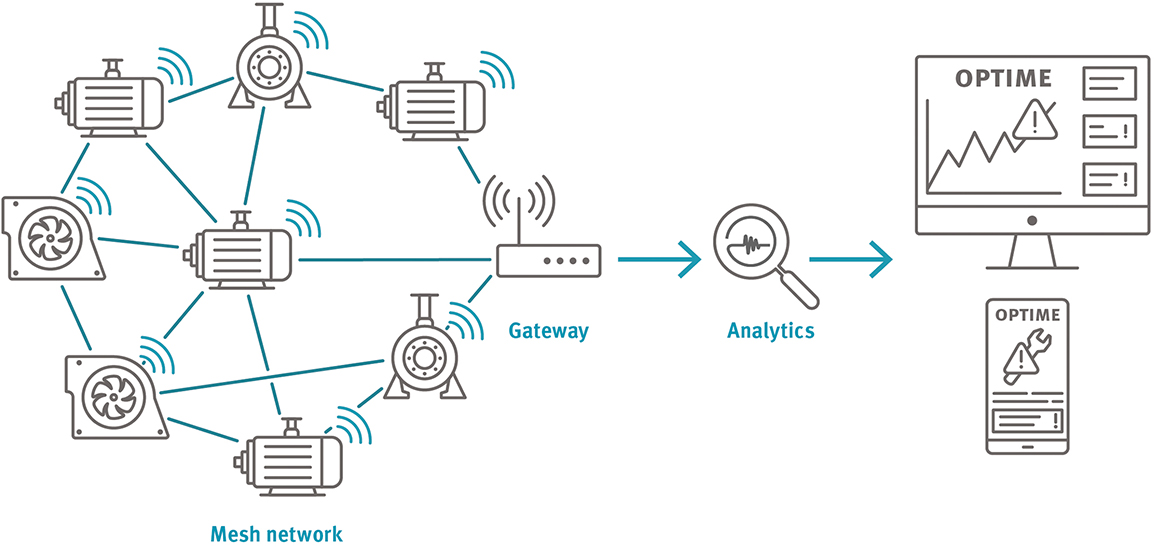

OPTIME enables early detection of potential machine damage and errors.

Condition monitoring

Schaeffler supplies its customers with intelligent, connected systems and components for different applications, whether wind turbine, production machine, or railway vehicle. Predictive machine monitoring receives special attention in order to control functionality, detect initial deviations from regular operation at an early stage, and schedule maintenance at the optimal time. One example is OPTIME, an application solution for automated, sensor-controlled condition monitoring for industrial systems. The newly developed system can predict malfunctions weeks in advance and provides information about the causes, as it continuously and automatically carries out analyses based on algorithms. This not only offers economic benefits, but also has a positive impact on the service life and energy consumption of the connected machines.

More information on industrial solutionsSchaeffler OPTIME

The easily scalable system consists of wireless, battery-powered vibration sensors, a gateway, and an app to visualize the resulting analysis data.

Customer Success Story - Finnsementti uses Schaeffler OPTIME.

Aftermarket in transition

While digitalization takes a critical look at even the most established business models, it also offers new opportunities for data-based innovations. This trend is especially relevant when it comes to online trading for automotive spare parts. Schaeffler has responded to this development with an increased focus on digital sales opportunities and has already established a new platform for digital sales in China. Schaeffler has also completed the assembly and packaging center for Europe in Halle/Saale: The “Aftermarket Kitting Operation Europe” (AKO Europe) represents yet another step towards ensuring a tailored, agile delivery of spare parts. The AKO will cover at least 60 % of global stocks by 2023 and consolidate delivery of spare parts for the Automotive Aftermarket, thanks to digital solutions. CO2 emissions will drop by around 20 % as a result of the shortened transport routes and higher transport capacities.

More information on the AftermarketTogether for more climate action

Effective climate protection requires a high degree of agility and adaptability. As one of the world’s leading automotive and industrial suppliers, Schaeffler develops solutions and components for ...

Out of the crisis: Stronger together

As a partner to the automotive industry, the Automotive OEM division is meeting the challenge of significantly reducing CO2 emissions in the mobility sector. Schaeffler sees ...